The equipment and plant that drive the refinery has been permanently shut down and the plant has effectively been dismantled internally; only the shells and structures remain. All facilities are being cleaned and flushed, ready for future demolition, with a small number of facilities being preserved for potential reuse or sale. At the same time, our site remediation of the groundwater that has been contaminated by hydrocarbons in the past, continues, and this is working: through our monitoring, we have seen a measurable decrease in the size of the contamination on our site and this will continue in the future.

Impact on our environment

We take our environmental responsibilities very seriously and work closely with our community and local Iwi to protect and enhance the coastline upon which we operate.

As part of our resource consent renewal and in preparation for our transition, we have undertaken extensive investigation of the impacts of our operations, and we found that there has been minimal impact beyond our boundary or risk of harm to the environment. Our operations remains firmly in line with the heavy industrial zoning of the Marsden Point area. We also worked closely with the Northland Regional Council and Iwi, as a consequence a Resource Consent was granted with a 35-year term to continue operating our heavy industrial site and set sound environmental standards for the management of our site over this time.

We regularly monitor the 140 wells on the site to provide us with a good picture of what is happening below our site. We have 5 recovery wells on site to contain and recover historic hydrocarbon contamination. These wells are monitored twice a week. We also monitor our perimeter wells on a monthly basis to ensure no hydrocarbons leave the site. We undertake soil sampling as part of our regular maintenance and project work to check for contamination and ensure the appropriate management of the soil.

Read more about our environmental management plans here: https://channelnz.com/community-sustainability/environment/

Site remediation

Unlike other industrial sites in New Zealand, there are no stockpiles of leftover toxic materials from oil refining that need to be disposed of at Marsden Point. That is because, when we were operating as a Refinery, we recycled, reused, or sold all of the by-products and waste from the refining process: from CO2 and bitumen to sulphur for fertilisers. Other waste such as catalyst was sent offsite for reprocessing or disposal.

We do know, however, that there is an ongoing need to remediate groundwater. Over the years that we ran the refinery, there has been hydrocarbon leakage beneath the now shutdown process plant. To fix this, our extensive groundwater remediation network of 140 wells, spread across our entire site are continuously operating to contain, and reduce the contamination, and have been for some years. And it’s working: we have seen a measurable decrease in the size of this legacy contamination, and we expect to see this continue to decline over the next few years now that we have stopped refining. We will continue working to fix this legacy contamination, and we have allocated funding as part of our ongoing costs to operate the terminal to continue this important work and ensure that the groundwater that leaves our site is free of hydrocarbons.

Other environmental management processes

Regular monitoring and testing of our groundwater well network to measure hydrocarbon contamination under the site

Monitoring of the 28 wells around our boundary. This provides a good picture of the groundwater quality leaving our site

Use of recovery wells which contain and remove hydrocarbon contamination under the site

Management of earthworks and site disturbance in accordance with our Ground Contamination Management Plan

Assessment of soils during works where they are potentially contaminated to determine if the soil is suitable for use on site

A robust permit to work system, which requires us to put in place controls to minimise risk to our workers and the environment. All work on site requires a permit to work.

Clean up of any leaks or spillages on site

An awareness of historic site practices which ensures adequate environmental controls are in place prior to the execution of any significant works on site.

Decommissioning and Demolition

An important part of the closure of any heavy industrial process, is the decommissioning of the assets that are no longer required. We have now completed over 70 percent of the decommissioning work, and only the shells and structures of the refinery remain. This is a permanent step, and involves cleaning, depressurising, isolation and removal of internal parts and some demolition works.

The refinery will be left in a safe and structurally sound state ready for demolition in the future. This will not be required for at least 10-years and allows time for us to explore options for future repurposing of these parts of the site. Options include renewable fuels such as hydrogen and sustainable aviation fuel and early-stage work is underway to investigate whether production of these renewable fuels at Marsden Point might be feasible in the future.

As part of our financial planning, we have a budget for our conversion project of between $200-$220 million a significant portion of which is for our decommissioning work, and the largest share of this is being spent with local Northland companies supporting us to complete these works. A further $50 million has been allocated for the cost of future demolition works at the site.

Completed work

- All catalyst and major internals have been removed to be sent for recycling or metals recovery

- Cables cut at ground level in preparation for final demolition

- 90% of the heat exchanger removals are complete and have been removed from site for recycling

- Isolation and permanent disconnection of electrical supply systems

- Selected units that could be sold or reused in future renewable energy projects have been preserved.

Work underway

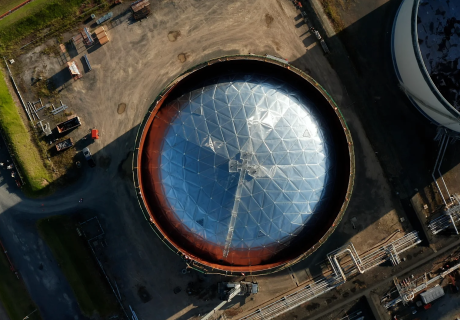

- Repurposing of crude tanks to store refined fuels and support New Zealand’s fuel security

- Upgrading of Tank containment systems – which are the important safety systems to prevent an oil spill.

- Installation of automatic fire protection systems to make sure we have the latest fire protection technology in use on our site

- Continued operation of wastewater systems to ensure all wastewater is treated and we are continuing to meet our Resource Consent conditions

- Monitoring of all site water run off to ensure that we continue to have a good understanding of the quality of the groundwater leaving our site

- Decontamination of process units, and removal of hydrocarbons for return to customers. Any remaining hydrocarbons will then be removed from site to an authorised facility

- Steam and chemical cleaning of equipment

- Decommissioning of tanks, which involves oil recovery and tank cleaning.

Decommissioning to date by the numbers

- 1530 tonnes of catalyst removed and ready for recycling offshore

- 3451 disconnections of electrical equipment completed

- 1,255 tonnes of steel sent for recycling

- 215 heat exchangers removed for recycling

- More than 100 columns and vessels opened and cleaned

- 99% of all hydrocarbons removed from processing units

Find out more

Read our community information flyer where you can find out more about this important work